The new 2014 Ram ProMaster, Ram Commercial’s latest addition to its vehicle lineup, takes its place in the expanding, purpose-built, full-size van segment with a number of best-in-class features focused on the commercial customer, according to the automaker.

“Our fleet customers are going to appreciate the remarkable versatility of the new 2014 Ram ProMaster full-size van, from its two roof heights to its multiple wheelbases and body lengths,” said Peter Grady, vice president of Network Development & Fleet for Chrysler. “The new Ram ProMaster will provide our fleet customers with numerous product advantages, from its class-exclusive front-wheel-drive to its best-in-class fuel economy.

Customers will value the reliability of the ProMaster, designed for the North American market but based on one of the most popular vans in Europe, the front-wheel-drive Fiat Ducato, in production for more than 30 years.”

The new vehicle is Ram’s first shared truck collaboration with Fiat Professional.

Production for the 2014 Ram ProMaster is scheduled to begin in the second quarter of 2013. All configurations will be produced at the Saltillo Commercial Truck Assembly Plant in Saltillo, Mexico.

The ProMaster offers two roof heights (90 inches and 101 inches), three wheelbases (118 inches, 136 inches, and 159 inches), and four body lengths (195 inches, 213 inches, 236 inches, and 250 inches).

Engineered for North America

Conceived and developed in Italy, Ram’s new van underwent extensive, extreme-duty testing to prepare for its North American debut.

Standard on the ProMaster will be the 3.6L Pentastar V-6, rated at 280 hp with a peak torque of 258 lb.-ft. Recommended oil-change intervals for this engine range up to 10,000 miles. But, an intelligent oil-servicing system that monitors vehicle usage will trigger an alert when service is most appropriate.

The 2014 Ram ProMaster marks the North American introduction of a 174-hp 3.0L inline four-cylinder EcoDiesel engine, which generates peak torque of 295 lb.-ft. at just 1,400 rpm. The engine features a number of refinements, including internal engine components, turbo, and emissions controls.

Also, an oil-level sensor contributes to an oil-change schedule of up to 18,500 miles for the 3.0L engine, helping reduce total cost of ownership.

Two transmission options are available on the new ProMaster: the 62TE automatic transmission and the M40 automated manual transmission. The trailer/tow program comes standard with the 62TE automatic transmission. A new M40 automated manual, exclusive to the 3.0L EcoDiesel, is also available.

The ProMaster offers two roof heights (90 inches and 101 inches), three wheelbases (118 inches, 136 inches, and 159 inches), and four body lengths (195 inches, 213 inches, 236 inches, and 250 inches).

Additionally, the ProMaster offers both a chassis cab and cutaway from the factory. The van’s segment-exclusive front-wheel-drive system and its unibody frame architecture make the van significantly lighter than others in its segment, according to the manufacturer.

It can achieve a payload capacity up to 5,145 lbs. and a maximum towing capacity up to 5,100 lbs. The GCWR is 11,500 lbs. for the 3.6L V-6, and 12,500 lbs. for the 3.0L I-4 EcoDiesel.

Upfitter Friendly

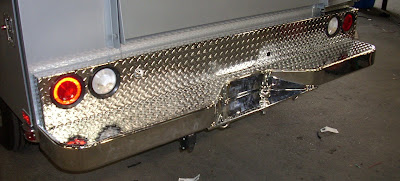

The body-integral construction and multiple configurations provide the ability to upfit for a large variety of job applications.

Side walls are nearly 90 degrees in relation to the cargo compartment floor, providing the ability to install shelving in the van without reducing standing and shoulder space.

The ProMaster also features a standard sliding door on the passenger side with an optional sliding door on the driver’s side. The sliding door openings are based on roof height — 49 inches by 60 inches for the low-roof model and 49 inches by 70 inches for high-roof models. An available two-position rear clamshell door swings open up to 260-degrees, folding almost flat to the side of the van. All three door openings enable forklift pallet loading and unloading.

Looking Good, Inside & Out

The front of the new ProMaster is identified by a broad wraparound bumper and twin-reflector headlamp clusters. The ProMaster leads with a hexagon-shaped crosshair grille, featuring the Ram’s head logo. The cab-forward, short dash to front axle design pushes the nose inward and the headlamps upward. According to Ram, this design provides higher passenger seating positions and better visibility — important for safety and commercial users.

A step is also designed into both front bumper corners, making it easier to clean the windscreen from either side.

The new full-size van also features plenty of real estate on all four sides, allowing for businesses to post signage and graphics.

Although much was borrowed from the Fiat version, Ram designers made alterations for U.S. customers, according to the automaker.

The van is fitted with up to 17 tie-down rings with 1,000-lb. rating, which fold away to maintain a flat floor, easing the process of loading and unloading. Available partitions also protect passengers from the possibility of load shift in the cabin.

Safety First

Ram’s new full-size van offers more than 35 active and passive safety and security features. It also includes standard electronic stability control (ESC), hosting a number of technologies such as trailer-sway control. Ram ProMaster features a ParkView backup camera and ParkSense with audible warning, all of which are useful when maneuvering a large van.

The standard ESC system on the new Ram ProMaster is a four-channel (independent control to all four corners of the vehicle) active handling system that links the vehicle’s dynamic control systems to assist the driver in maintaining control under demanding or adverse conditions such as wet, snow-covered, or icy roads; tight turns; and evasive maneuvers. In effect, the ESC determines the driver’s intentions and optimizes overall vehicle control to keep the dynamic forces within select limits in any driving situation — so control seems almost intuitive.

ProMaster customers can make the best use of their valuable time by leveraging Uconnect’s easy-to-learn, easy-to-use controls. Hands-free calling is made convenient via Bluetooth technology. Similarly, the truck’s hands-free text-reply feature enables customers to quickly deliver messages.

A full-color, five-inch touchscreen is available with GPS navigation, providing customers the ability to chart time-saving routes to their destinations. Uconnect Web, powered by Autonet Mobile, is available to U.S. customers. This system delivers continuous Internet connectivity, creating an efficient workspace and real-time information access on the go.

March 2013, Work Truck Magazine - Cover Story

By Lauren Fletcher

Tags: Ram ProMaster, Ram Commercial Trucks